supply chain

Mathematical optimization for Industry 4.0

Thu, 05/20/2021 - 09:40 — admin This academic course started the third edition of the Master in Industry 4.0 of the UPC School. The main objective of the master's degree in Industry 4.0 is to train professionals to understand the complexities and challenges of Industry 4.0 in a transversal way. I participate in this master giving a course on mathematical optimization for industry 4.0. In the first part of the course, we review the role of mathemnatical optimization, operations research and analytics in Ind. 4.0, analyse some case studies on mathematical optimization models in supply chain and energy industry. In the second part, the theoretical and computational basis of mathematical optimization are presented and applied by the students to solve a complete optimization project in supply and distribution chain using mathematical optimization modeling software.

This academic course started the third edition of the Master in Industry 4.0 of the UPC School. The main objective of the master's degree in Industry 4.0 is to train professionals to understand the complexities and challenges of Industry 4.0 in a transversal way. I participate in this master giving a course on mathematical optimization for industry 4.0. In the first part of the course, we review the role of mathemnatical optimization, operations research and analytics in Ind. 4.0, analyse some case studies on mathematical optimization models in supply chain and energy industry. In the second part, the theoretical and computational basis of mathematical optimization are presented and applied by the students to solve a complete optimization project in supply and distribution chain using mathematical optimization modeling software.

A multistage stochastic programming model for the strategic supply chain design

Wed, 07/11/2018 - 11:30 — admin| Publication Type | Conference Paper |

| Year of Publication | 2018 |

| Authors | Daniel Ramón-Lumbierres; F.-Javier Heredia; Robert Gimeno Feu; Julio Consola; Román Buil Giné |

| Conference Name | 23th International Symposium on Mathematical Programming |

| Conference Date | 01-06/07/2018 |

| Conference Location | Bordeaux |

| Editor | Mathematical Optimization Society (MOS) |

| Type of Work | contributed presentation |

| Key Words | research; supply chain; postponment; multistage stochastic programming |

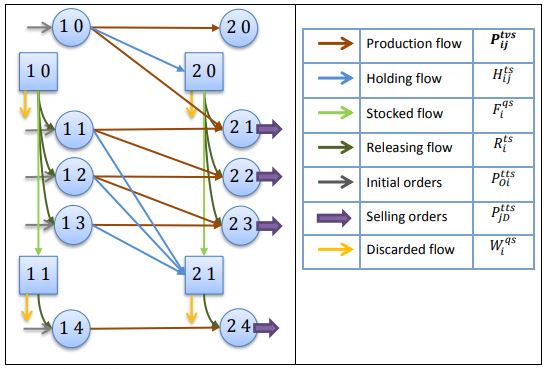

| Abstract | Supply chain management has been widely developed through the evolution of manufacturing, distribution, forecasting and customer behavior, encouraging the introduction of postponement strategies in its various forms. At these strategies, semi-finished goods are stored in certain operations of the chain, called decoupling points, waiting for the placement of demand orders, which trigger production flows from decoupling points to the remainder operations. Such a design problem facing the speculation/postponement paradigm must intrinsically include elements that "unveil" demand orders when they are placed, that is, the modelling approach should keep demand orders as random variables until their placement, when they are disclosed. This work proposes a multi-stage stochastic programming model that decides the optimal allocation of decoupling points, as well as a process selection among alternative designs for any general supply chain case, where the stochastic parameters, demands by period and product, are represented through a scenario tree, which is in turn generated using the forecasting. Both a risk-neutral model and a risk-aversion approach with stochastic dominance constraints are presented and solved with multi-stage instances of test cases based on real manufacturing problems defined in collaboration with the Accenture consultancy company. |

| URL | Click Here |

| Export | Tagged XML BibTex |

Optimising data analytics for industry 4.0

Thu, 03/01/2018 - 14:27 — admin| Publication Type | Conference Paper |

| Year of Publication | 2018 |

| Authors | F.-Javier Heredia |

| Conference Name | Maths for Industry 4.0 |

| Conference Date | 19/02/2018 |

| Conference Location | Barcelona |

| Type of Work | Round table |

| Key Words | research,; industrial mathematics; industry 4.0; BGSMath |

| Abstract | “Maths for Industry 4.0” will showcase how academic excellence at BGSMath is helping companies becoming digital. Join us to learn about successful collaborative initiatives, such as industrial doctoral theses, as well as the range of expertise you could benefit from. The workshop will be closed by a round table on Data Analytics. Our experts will discuss common challenges and trends across sectors, and how mathematical creativity enable solutions for supply chain, risk management, control and monitoring. This activity belongs to the Mobile Week Barcelona and it’s an open space for reflexion on digital transformation through art, science and technology. |

| URL | Click Here |

| Export | Tagged XML BibTex |

New website for the research project "Strategical Models in Supply Chain Design"

Fri, 02/16/2018 - 11:58 — admin

A new website for the research project Strategical Models in Supply Chain Design has been deployed at

A new website for the research project Strategical Models in Supply Chain Design has been deployed at

https://gnom.upc.edu/en/projects/supply-chain/smscd-2017

This site is intended to improve the comunication between the different partners of the project (UPC-Accenture Analytics Barcelona - Accenture Labs Silicon Valley) and to show the progress of this project. All the documentacion related with the project is going to be available at this site (meetings, reports, papers, conference contributions), although some of them will be secured. If you would like to acess to some protected document please send an e-mail to f.javier.heredia@upc.edu

Comparison of production strategies and degree of postponement when incorporating additive manufacturing to product supply chains

Thu, 08/31/2017 - 23:00 — admin| Publication Type | Proceedings Article |

| Year of Publication | 2017 |

| Authors | J. Minguella-Canela; A. Muguruza; D.R. Lumbierres: F.-Javier Heredia; R. Gimeno; P. Guo; M. Hamilton; K.Shastry, S.Webb |

| Conference Name | Manufacturing Engineering Society International Conference 2017, MESIC 201 |

| Series Title | Procedia Manufacturing |

| Volume | 13 |

| Pagination | 754-761 |

| Conference Start Date | 18/06/2017 |

| Publisher | Elsevier |

| Conference Location | Vigo, Spain |

| Editor | Jorge Salguero, Enrique Ares |

| ISSN Number | 2351-9789 |

| Key Words | Additive Manufacturing; Ultra-postponement; Supply Chain; research; paper |

| Abstract | The best-selling products manufactured nowadays are made in long series along rigid product value chains. Product repetition and continuous/stable manufacturing is seen as a chance for achieving economies of scale. Nevertheless, these speculative strategies fail to meet special customer demands, thus reducing the effective market share of a product in a range. Additive Manufacturing technologies open promising product customization opportunities; however, to achieve it, it is necessary to delay the production operations in order to incorporate the customer’s inputs in the product materialization. The study offered in the present paper compares different possible production strategies for a product (via conventional technologies and Additive Manufacturing) and assesses the degree of postponement that it would be recommended in order to meet a certain demand distribution. The problem solving is calculated by a program containing a stochastic mathematical model which incorporates extensive information on costs and lead times for the required manufacturing operations. |

| URL | Click Here |

| DOI | https://doi.org/10.1016/j.promfg.2017.09.181 |

| Export | Tagged XML BibTex |

A new contribution on incorporating additive manufacturing to product supply chains

Thu, 08/31/2017 - 23:00 — admin A new result of the research project Digitalizing Supply Chain Strategy with 3D Printing with Accenture TechLabs and Center for Analytics has been presented in the Manufacturing Engineering Society International Conference 2017 , MESIC 2017. The study compares different possible production strategies for a product (via conventional technologies and Additive Manufacturing) and assesses the degree of postponement that it would be recommended in order to meet a certain demand distribution. The problem solving is calculated by a program containing a stochastic mathematical model which incorporates extensive information on costs and lead times for the required manufacturing operations. This study was published in Procedia Manufacturing.

A new result of the research project Digitalizing Supply Chain Strategy with 3D Printing with Accenture TechLabs and Center for Analytics has been presented in the Manufacturing Engineering Society International Conference 2017 , MESIC 2017. The study compares different possible production strategies for a product (via conventional technologies and Additive Manufacturing) and assesses the degree of postponement that it would be recommended in order to meet a certain demand distribution. The problem solving is calculated by a program containing a stochastic mathematical model which incorporates extensive information on costs and lead times for the required manufacturing operations. This study was published in Procedia Manufacturing.

Comparison of production strategies and degree of postponement when incorporating additive manufacturing to product supply chains

Thu, 07/27/2017 - 13:34 — admin| Publication Type | Conference Paper |

| Year of Publication | 2017 |

| Authors | J. Minguella-Canela; A. Muguruza; D.R. Lumbierres; F.-Javier Heredia; R. Gimeno; P. Guo; M. Hamilton; K. Shastry; S. Webb |

| Conference Name | Manufacturing Engineering Society International Conference 2017, MESIC 2017, 28-30 |

| Conference Date | 28-30/07/2017 |

| Publisher | Elsevier |

| Conference Location | Vigo, Spain |

| Type of Work | Contributed presentation |

| Key Words | research; Additive Manufacturing; Ultra-postponement; Supply Chain; stochastic programming |

| Abstract | The best-selling products manufactured nowadays are made in long series along rigid product value chains. Product repetition and continuous/stable manufacturing is seen as a chance for achieving economies of scale. Nevertheless, these speculative strategies fail to meet special customer demands, thus reducing the effective market share of a product in a range. Additive Manufacturing technologies open promising product customization opportunities; however, to achieve it, it is necessary to delay the production operations in order to incorporate the customer’s inputs in the product materialization. The study offered in the present paper compares different possible production strategies for a product (via conventional technologies and Additive Manufacturing) and assesses the degree of postponement that it would be recommended in order to meet a certain demand distribution. The problem solving is calculated by a program containing a stochastic mathematical model which incorporates extensive information on costs and lead times for the required manufacturing operations. |

| URL | Click Here |

| Export | Tagged XML BibTex |

Strategical models in supply chain design through mathematical optimization.

Thu, 06/08/2017 - 17:39 — admin| Publication Type | Funded research projects |

| Year of Publication | 2016 |

| Authors | F.-Javier Heredia |

| Type of participation | Leader |

| Duration | 11/2016-11/2019 |

| Funding organization | Accenture Technology Labs |

| Partners | Accenture Technology Labs (Silicon Valley), Accenture Analytics Innovation Center (Barcelona) |

| Full time researchers | 2 |

| Budget | 132.532,43€ |

| Project code | I-01507, I-01508 |

| Key Words | research; supply chain; manufacturing; private; project; Accenture |

| Export | Tagged XML BibTex |

Optimización de costos logísticos: Un caso de estudio de una empresa de plásticos

Wed, 03/15/2017 - 14:41 — admin| Publication Type | Proceedings Article |

| Year of Publication | 2016 |

| Authors | Miguel Mata Perez; F.-Javier Heredia; Claudia Morales Carreon |

| Conference Name | Congreso Internacional de Logística y Cadena de Suministro 2016 CILOG2016 |

| Series Title | Sesiones técnicas |

| Volume | 2 |

| Pagination | 38-46 |

| Conference Start Date | 3-7/09/2016 |

| Publisher | Asociación Mexicana de Logística y Cadena de Suministro A.C. |

| Conference Location | Yucatán, México |

| Key Words | research; supply chain; distribution chain; logistics; paper |

| Abstract | Hoy en día los costos logísticos representan una gran oportunidad de mejora para las empresas siendo los costos de transporte y los costos de inventario los más representativos. En este trabajo se presenta un estudio de una empresa ubicada en la región, la cual incurre actualmente en altos costos logísticos en su proceso de importación de materia prima desde Asia hasta su filial en Monterrey, N.L. Por medio de un modelo matemático entero mixto se consigue minimizar los costos antes mencionados. El modelo tiene las siguientes características: es de ubicación de facilidades en cuatro etapas, multiproducto, multiperiodo y multitransporte. |

| Export | Tagged XML BibTex |

Optimización de costos logísticos: Un caso de estudio de una empresa de plásticos.

Wed, 03/15/2017 - 14:24 — admin| Publication Type | Conference Paper |

| Year of Publication | 2016 |

| Authors | Claudia Morales Carreon; F.-Javier Heredia; Miguel Mata Perez |

| Conference Name | Congreso Internacional de Logística y Cadena de Suministro 2016 |

| Conference Date | 3-7/09/2016 |

| Conference Location | Yucatán, Máxico |

| Type of Work | contributed |

| Key Words | research; supply chain; distribution chain; logistics |

| Abstract | Hoy en día los costos logísticos representan una gran oportunidad de mejora para las empresas siendo los costos de transporte y los costos de inventario los más representativos. En este trabajo se presenta un estudio de una empresa ubicada en la región, la cual incurre actualmente en altos costos logísticos en su proceso de importación de materia prima desde Asia hasta su filial en Monterrey, N.L. Por medio de un modelo matemático entero mixto se consigue minimizar los costos antes mencionados. El modelo tiene las siguientes características: es de ubicación de facilidades en cuatro etapas, multiproducto, multiperiodo y multitransporte. |

| Export | Tagged XML BibTex |