Industry 4.0

Mathematical optimization for Industry 4.0

Thu, 05/20/2021 - 09:40 — admin This academic course started the third edition of the Master in Industry 4.0 of the UPC School. The main objective of the master's degree in Industry 4.0 is to train professionals to understand the complexities and challenges of Industry 4.0 in a transversal way. I participate in this master giving a course on mathematical optimization for industry 4.0. In the first part of the course, we review the role of mathemnatical optimization, operations research and analytics in Ind. 4.0, analyse some case studies on mathematical optimization models in supply chain and energy industry. In the second part, the theoretical and computational basis of mathematical optimization are presented and applied by the students to solve a complete optimization project in supply and distribution chain using mathematical optimization modeling software.

This academic course started the third edition of the Master in Industry 4.0 of the UPC School. The main objective of the master's degree in Industry 4.0 is to train professionals to understand the complexities and challenges of Industry 4.0 in a transversal way. I participate in this master giving a course on mathematical optimization for industry 4.0. In the first part of the course, we review the role of mathemnatical optimization, operations research and analytics in Ind. 4.0, analyse some case studies on mathematical optimization models in supply chain and energy industry. In the second part, the theoretical and computational basis of mathematical optimization are presented and applied by the students to solve a complete optimization project in supply and distribution chain using mathematical optimization modeling software.

Optimització de Reserves de Cable en Bobina (ORCaB)

Wed, 07/22/2020 - 12:00 — admin| Publication Type | Funded research projects |

| Year of Publication | 2020 |

| Authors | F.-Javier Heredia |

| Type of participation | Leader |

| Duration | 06/2020-12/2020 |

| Funding organization | Top Cable |

| Partners | - |

| Project code | C-11622 |

| Key Words | research; one dimensional cutting stock; private; project; manufacturing |

| Abstract | L’empresa Top Cable, líder en la fabricació de cables elèctrics, es planteja aplicar una millora en el seu ERP de gestió del magatzem, afegint-hi un nou mòdul que optimitzi i doni suggeriments a la logística del magatzem tenint en compte les noves arribades i l’stock que hi hagi present. |

| Export | Tagged XML BibTex |

New paper published in International Journal of Production Research.

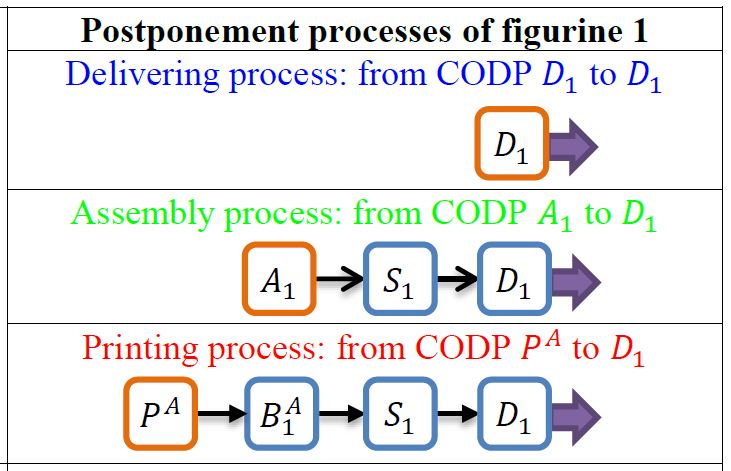

Tue, 07/21/2020 - 16:46 — admin The paper entitled Optimal Postponement in Supply Chain Network Design Under Uncertainty: An Application for Additive Manufacturing (preprint ) has been published in the International Journal of Production Research. This paper is the result of projects Strategical Models in Supply Chain Design, and Digitalizing Supply Chain Strategy with 3D Printing a successful collaboration between GNOM with Accenture Technology Labs (Silicon Valley), Accenture Analytics Innovation Center (Barcelona) and the Fundació CIM-UPC. This study This study presents a new two-stage stochastic programming decision model for assessing how to introduce some new manufacturing technology into any generic supply and distribution chain. It additionally determines the optimal degree of postponement, as represented by the so-called customer order decoupling point (CODP), while assuming uncertainty in demand for multiple products. Finally, it presents and analyses a case study for introducing additive manufacturing technologies.

The paper entitled Optimal Postponement in Supply Chain Network Design Under Uncertainty: An Application for Additive Manufacturing (preprint ) has been published in the International Journal of Production Research. This paper is the result of projects Strategical Models in Supply Chain Design, and Digitalizing Supply Chain Strategy with 3D Printing a successful collaboration between GNOM with Accenture Technology Labs (Silicon Valley), Accenture Analytics Innovation Center (Barcelona) and the Fundació CIM-UPC. This study This study presents a new two-stage stochastic programming decision model for assessing how to introduce some new manufacturing technology into any generic supply and distribution chain. It additionally determines the optimal degree of postponement, as represented by the so-called customer order decoupling point (CODP), while assuming uncertainty in demand for multiple products. Finally, it presents and analyses a case study for introducing additive manufacturing technologies.

Optimal Postponement in Supply Chain Network Design Under Uncertainty: An Application for Additive Manufacturing

Tue, 07/21/2020 - 15:49 — admin| Publication Type | Journal Article |

| Year of Publication | 2021 |

| Authors | Daniel Ramón-Lumbierres; F.-Javier Heredia; Joaquim Minguella-Canela; Asier Muguruza-Blanco |

| Journal Title | International Journal of Production Research |

| Pages | 5198-5215 |

| Journal Date | 07/2020 |

| Publisher | Taylor&Francis |

| ISSN Number | 0020-7543 |

| Key Words | manufacturing; postponement; stochastic programming; supply chain network design; 3D printing; additive manufacturing; research; paper |

| Abstract | This study presents a new two-stage stochastic programming decision model for assessing how to introduce some new manufacturing technology into any generic supply and distribution chain. It additionally determines the optimal degree of postponement, as represented by the so-called customer order decoupling point (CODP), while assuming uncertainty in demand for multiple products. To this end, we propose here the formulation of a generic supply chain through an oriented graph that represents all the deployable alternative technologies, which are defined through a set of operations that are characterized by lead times and cost parameters. Based on this graph, we develop a mixed integer two-stage stochastic program that finds the optimal manufacturing technology for meeting each market’s demand, each operation’s optimal production quantity, and each selected technology’s optimal CODP. We also present and analyse a case study for introducing additive manufacturing technologies. |

| URL | Click Here |

| DOI | 10.1080/00207543.2020.1775908 |

| Preprint | http://hdl.handle.net/2117/327874 |

| Export | Tagged XML BibTex |

Research project with Top Cable on multiperiod one-dimensional cutting stock problem.

Wed, 04/22/2020 - 10:48 — admin On April 2020 a research project called Optimització de Reserves de Cable en Bobines has been settled with the company Top Cable, a international leader in cable technology. The purpose of the project is to engage a study to asses the suitability of mathematical optimization techniques to improve the procedure they currently apply to the fulfillment of the customer's orders. In this first part of the project a multiperiod extension of the one-dimensional cutting stock problem is going to be formulated to solve a instance of the company's demand supply problem.

On April 2020 a research project called Optimització de Reserves de Cable en Bobines has been settled with the company Top Cable, a international leader in cable technology. The purpose of the project is to engage a study to asses the suitability of mathematical optimization techniques to improve the procedure they currently apply to the fulfillment of the customer's orders. In this first part of the project a multiperiod extension of the one-dimensional cutting stock problem is going to be formulated to solve a instance of the company's demand supply problem.

A multistage stochastic programming model for the strategic supply chain design

Wed, 07/11/2018 - 11:30 — admin| Publication Type | Conference Paper |

| Year of Publication | 2018 |

| Authors | Daniel Ramón-Lumbierres; F.-Javier Heredia; Robert Gimeno Feu; Julio Consola; Román Buil Giné |

| Conference Name | 23th International Symposium on Mathematical Programming |

| Conference Date | 01-06/07/2018 |

| Conference Location | Bordeaux |

| Editor | Mathematical Optimization Society (MOS) |

| Type of Work | contributed presentation |

| Key Words | research; supply chain; postponment; multistage stochastic programming |

| Abstract | Supply chain management has been widely developed through the evolution of manufacturing, distribution, forecasting and customer behavior, encouraging the introduction of postponement strategies in its various forms. At these strategies, semi-finished goods are stored in certain operations of the chain, called decoupling points, waiting for the placement of demand orders, which trigger production flows from decoupling points to the remainder operations. Such a design problem facing the speculation/postponement paradigm must intrinsically include elements that "unveil" demand orders when they are placed, that is, the modelling approach should keep demand orders as random variables until their placement, when they are disclosed. This work proposes a multi-stage stochastic programming model that decides the optimal allocation of decoupling points, as well as a process selection among alternative designs for any general supply chain case, where the stochastic parameters, demands by period and product, are represented through a scenario tree, which is in turn generated using the forecasting. Both a risk-neutral model and a risk-aversion approach with stochastic dominance constraints are presented and solved with multi-stage instances of test cases based on real manufacturing problems defined in collaboration with the Accenture consultancy company. |

| URL | Click Here |

| Export | Tagged XML BibTex |

Optimising data analytics for industry 4.0

Thu, 03/01/2018 - 14:27 — admin| Publication Type | Conference Paper |

| Year of Publication | 2018 |

| Authors | F.-Javier Heredia |

| Conference Name | Maths for Industry 4.0 |

| Conference Date | 19/02/2018 |

| Conference Location | Barcelona |

| Type of Work | Round table |

| Key Words | research,; industrial mathematics; industry 4.0; BGSMath |

| Abstract | “Maths for Industry 4.0” will showcase how academic excellence at BGSMath is helping companies becoming digital. Join us to learn about successful collaborative initiatives, such as industrial doctoral theses, as well as the range of expertise you could benefit from. The workshop will be closed by a round table on Data Analytics. Our experts will discuss common challenges and trends across sectors, and how mathematical creativity enable solutions for supply chain, risk management, control and monitoring. This activity belongs to the Mobile Week Barcelona and it’s an open space for reflexion on digital transformation through art, science and technology. |

| URL | Click Here |

| Export | Tagged XML BibTex |