Supply Chain Network Design

New paper published in International Journal of Production Research.

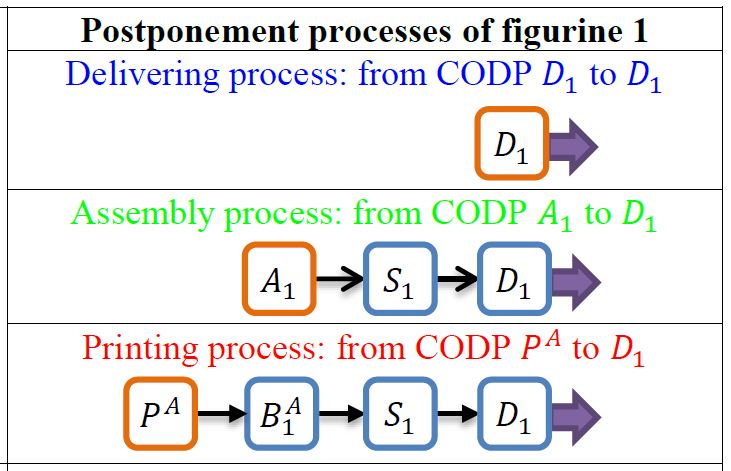

Tue, 07/21/2020 - 16:46 — admin The paper entitled Optimal Postponement in Supply Chain Network Design Under Uncertainty: An Application for Additive Manufacturing (preprint ) has been published in the International Journal of Production Research. This paper is the result of projects Strategical Models in Supply Chain Design, and Digitalizing Supply Chain Strategy with 3D Printing a successful collaboration between GNOM with Accenture Technology Labs (Silicon Valley), Accenture Analytics Innovation Center (Barcelona) and the Fundació CIM-UPC. This study This study presents a new two-stage stochastic programming decision model for assessing how to introduce some new manufacturing technology into any generic supply and distribution chain. It additionally determines the optimal degree of postponement, as represented by the so-called customer order decoupling point (CODP), while assuming uncertainty in demand for multiple products. Finally, it presents and analyses a case study for introducing additive manufacturing technologies.

The paper entitled Optimal Postponement in Supply Chain Network Design Under Uncertainty: An Application for Additive Manufacturing (preprint ) has been published in the International Journal of Production Research. This paper is the result of projects Strategical Models in Supply Chain Design, and Digitalizing Supply Chain Strategy with 3D Printing a successful collaboration between GNOM with Accenture Technology Labs (Silicon Valley), Accenture Analytics Innovation Center (Barcelona) and the Fundació CIM-UPC. This study This study presents a new two-stage stochastic programming decision model for assessing how to introduce some new manufacturing technology into any generic supply and distribution chain. It additionally determines the optimal degree of postponement, as represented by the so-called customer order decoupling point (CODP), while assuming uncertainty in demand for multiple products. Finally, it presents and analyses a case study for introducing additive manufacturing technologies.

Optimal Postponement in Supply Chain Network Design Under Uncertainty: An Application for Additive Manufacturing

Tue, 07/21/2020 - 15:49 — admin| Publication Type | Journal Article |

| Year of Publication | 2021 |

| Authors | Daniel Ramón-Lumbierres; F.-Javier Heredia; Joaquim Minguella-Canela; Asier Muguruza-Blanco |

| Journal Title | International Journal of Production Research |

| Pages | 5198-5215 |

| Journal Date | 07/2020 |

| Publisher | Taylor&Francis |

| ISSN Number | 0020-7543 |

| Key Words | manufacturing; postponement; stochastic programming; supply chain network design; 3D printing; additive manufacturing; research; paper |

| Abstract | This study presents a new two-stage stochastic programming decision model for assessing how to introduce some new manufacturing technology into any generic supply and distribution chain. It additionally determines the optimal degree of postponement, as represented by the so-called customer order decoupling point (CODP), while assuming uncertainty in demand for multiple products. To this end, we propose here the formulation of a generic supply chain through an oriented graph that represents all the deployable alternative technologies, which are defined through a set of operations that are characterized by lead times and cost parameters. Based on this graph, we develop a mixed integer two-stage stochastic program that finds the optimal manufacturing technology for meeting each market’s demand, each operation’s optimal production quantity, and each selected technology’s optimal CODP. We also present and analyse a case study for introducing additive manufacturing technologies. |

| URL | Click Here |

| DOI | 10.1080/00207543.2020.1775908 |

| Preprint | http://hdl.handle.net/2117/327874 |

| Export | Tagged XML BibTex |